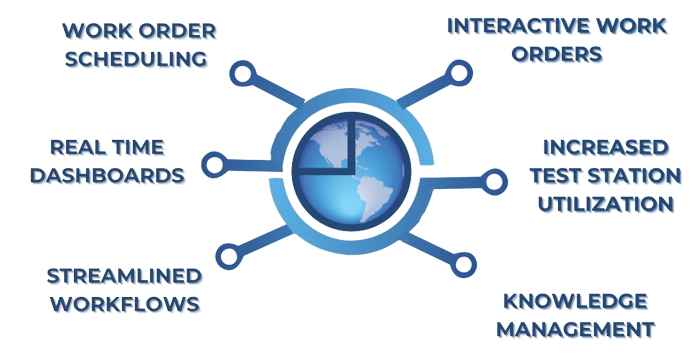

Hooks & Associates, Inc. (H&A) is a engineering firm that designs, fabricates, and installs automated test systems for the manufacturing industry. We specialize in psychrometric test chambers for testing unitary air conditioners, measurement and control systems for test labs and powerful software systems. We provide technology and expertise from the reading to report to automate the collection of lab data and streamline lab processes.